noncontact thickness measurement techniques|non contact thickness sensors : wholesaler Non-contact techniques that have been widely employed for thickness measurement of transparent plates and optical lenses are mostly based on low-coherence interferometry [1][2][3][4][5][6][7][8 .

Google's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languages.

{plog:ftitle_list}

web31 de dez. de 2022 · RESIDENT EVIL 4 DUBLADO PARA PC FRACO - #SERÁQUERODA?! #13---------------------------------------------------------------LEIA A DESCRIÇÃO--------------------.

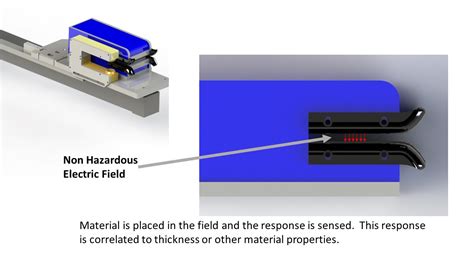

In this guide, we will discuss the most common non-contact measurement devices and methods to help you find the best measurement systems for your applications. Non-contact or touchless dimensional measurement devices are the modern new comer to an array of contact devices that have been traditionally used. Contact devices are discussed in this link on Common Contact . Thickness is a typical parameter related to length, of which measurements are conducted in various industrial fields, such as the automotive, aviation, ship-building, semiconductor, and display industries. Among various .In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is typically .

This paper presents a novel noncontact measurement technique that entails using a single-compound triple complementary split-ring resonator (SC-TCSRR) to determine the complex permittivity and thickness of a material under test (MUT). The proposed technique overcomes the problem engendered by the existence of air gaps between the sensor ground . Non-contact techniques that have been widely employed for thickness measurement of transparent plates and optical lenses are mostly based on low-coherence interferometry [1][2][3][4][5][6][7][8 .

The measurement of film thickness holds significance for various manufacturing and research facilities. Fluctuations in the thickness of paint or coating can impact multiple properties crucial to the end product, including color, gloss, hardness, adhesion, and .Advantages of non-contact measurement with displacement sensors include their non-destructive technique, ability for single-sided continuous thickness measurement, ability to cope with coatings, linings, etc., and high accuracy (0.1 mm . In general, the method of thickness measurement of thin-walled parts can be categorized into contact methods and non-contact methods. Contact methods such as coordinate measuring machine and contact profilometer use a mechanical probe to collect data by continuous scanning or gap sampling through the workpiece surface.

The non-contact measurement method allows the coating to be measured directly after application while it is still wet and provides the necessary accuracy and repeatability for controlling the process. . A., Kleyer, T. Non-Contact Coating Thickness Measurement Ensures Protection Against Corrosion. Int Surf Technol 13, 50–53 (2020). https . A Novel, Non-Contact NDT Scanner Case Study: Thickness Measurement, Debonding and Defects Detection in Metallic and Composite Parts February 2024 Journal of Physics Conference Series 2692(1):012024

Non-contact metrology involves the application of non-contact measurement techniques in the field of metrology—the science of measurement. This approach encompasses a wide range of methods and instruments designed to measure objects with high accuracy and repeatability, often down to the micrometer or nanometer scale. Non-contact measurement of the thickness of a surface film using a superimposed ultrasonic standing wave. . Most methods used to measure the thickness of thin liquid or solid surface films and coatings need access to the coated surface. In this work reflected ultrasonic pulses were used to measure a coating thickness from a solid back face . Among these surface profile measurement techniques, the optical interferometry based techniques have gained most widespread use, not only are they non-contact measurement modes, which is important where the target surfaces are physically inaccessible or susceptible to damage when the surfaces are contacted with physical probes, but also the .

Here are some examples of coating thickness measurement tools and methods. . Standard Test Method for Determining Plastic Film Thicknessand Thickness Variability Using a Non-Contact Capacitance Thickness Gauge: ASTM D7378-16: Standard Practice for Measurement of Thickness of Applied Coating Powders to Predict Cured Thickness: Non-contact method of thickness measurement for the transparent plate by using laser auto-focus scanning probe . 13 and other methods to achieve non-contact precision measurement of material . The insulating coating is usually made by Al 2 O 3 ceramic sprayed on the base metal layer of bearings [4]; it is characterized by insulation, non-transparency, and precise thickness; Moreover, the bearing’s surface of the metal layer is curved, so the coating has a curved structure, and thus many methods are invalid to measure its thickness.In addition, .

A key function to achieving this is accurate plating thickness measurement. The collected data helps determine if the job is running as it should, or if adjustments need to be made to achieve the stated thickness . For transparent films, many optical methods are used for thickness measurements, such as phase shifting interferometry and equal-path interferometer 1,2, astigmatic method 3, multiple beam . In addition, interferometry requires a highly reflective surface to obtain interference fringes. In both methods, the film thickness is measured at a specific point. As a result, the uniformity of the film is a critical parameter that determines the accuracy of thickness. Non-Destructive, Non-Contact Methods to Measure Thin Film Thickness . In addition, it compares the application scenarios of other techniques and the influence of the environment on detection results.,Ultrasonic measurement stands out due to its widespread adaptability, making it suitable for oil film thickness detection in various states and monitoring continuous changes in oil film thickness. Different methods .

V arious methods of NDT are used for the measurement of coating thickness – paint thickness, plating thickness, anodising etc. These methods may be X-ray, electron backscatter, magnetic, etc and the Table gives a broad guide to the most appropriate methods for various coatings and substrates. Appropriate NDT techniques for coating thickness .

On the surface, thickness seems like an easy measurement to take, as dimensional measurements go. You have two big, flat, parallel planes on which to plant your gage. For hard materials, like metal sheet, you can use three of the four measuring capabilities of a slide caliper. A micrometer does very nicely, too, if you have the time and need the accuracy. Compared to conventional techniques, TPI has the advantage that it is a non-contact method and that it is able to spatially resolve the thickness uniformity distribution information by two .

Thin Solid Films, 124 (1985) 249-257 PREPARATION AND CHARACTERIZATION 249 THIN FILM THICKNESS MEASUREMENT: A COMPARISON OF VARIOUS TECHNIQUES* A. PIEGARI AND E. MASETTI Laboratorio Film Sottili, Comitato Nazionale per la ricerca a per to sviluppo dell'Energia Nucleare a delle Energie Alternative, Via Angutllarese Km 1300, 00060 . This page is dedicated to educating our customers on the different methods available to measure the thickness of plastic film. . SolveTech is an ASTM member and worked with the ASTM to developed new standard D8136 for non-contact thickness gauging which has better R&R (repeatability and reproducibility). It also defines profiling a film and .Coating thicknesses measurement - simply, quickly and reliably with our wide range of different measurement solutions and methods. Find out more! . Coating thickness measurement/Dry film thickness measurement is used to determine the thickness of coatings on components and to monitor the coating process. . Measure your coatings non .

non contact thickness sensors

This paper proposes an online, non-contact metal film thickness measurement system based on eddy current sensing. The slope of the lift-off curve (LOC) is used for characterizing target thickness. Theoretical derivation was conducted to prove .

Adhesive Peel Tester distributing

Adhesive Peel Tester agent

Esteja preparado para passar o final de semana em Boituva .

noncontact thickness measurement techniques|non contact thickness sensors